Effective techniques for inventory control are a critical element in successful business management to reduce costs of excess stocks to maximise profits. Inventory control procedures are significant for every business regardless of its size; for a small retailer or a big manufacturer, inventory control methods should be applied. The above inventory controlling techniques depict the appropriate balance of holding costs that envisage product availability for business survival.

The practice of inventory and control does not refer simply to ensuring that there are products to sell but a system of logistic that meets demand perfectly. From the above perspectives of the types of control in management, it indicates that the inventory control should apply the correct method in order to make the right decisions in improving of efficiency, reducing cost and satisfying of the customer.

Why Effective Inventory Control is Essential

The control of inventory impacts nearly every aspect of a business’s operations. Ineffective inventory control can result in overstocking, stockouts, high holding costs, and unhappy consumers. To control inventory effectively, companies need to implement inventory control techniques that allow for flexibility and precision. This ensures that stock levels remain aligned with customer demand, reducing waste and enhancing profitability.

It stresses that accuracy of storing and managing inventory is actually more necessary in organizations for foods and other specialized sectors or enterprises with high temporal fluctuations. Using Techniques for Inventory Control and control that include EOQ, JIT inventory and ABC analysis companies can leverage it to optimize processes, cash and the entire supply chain.

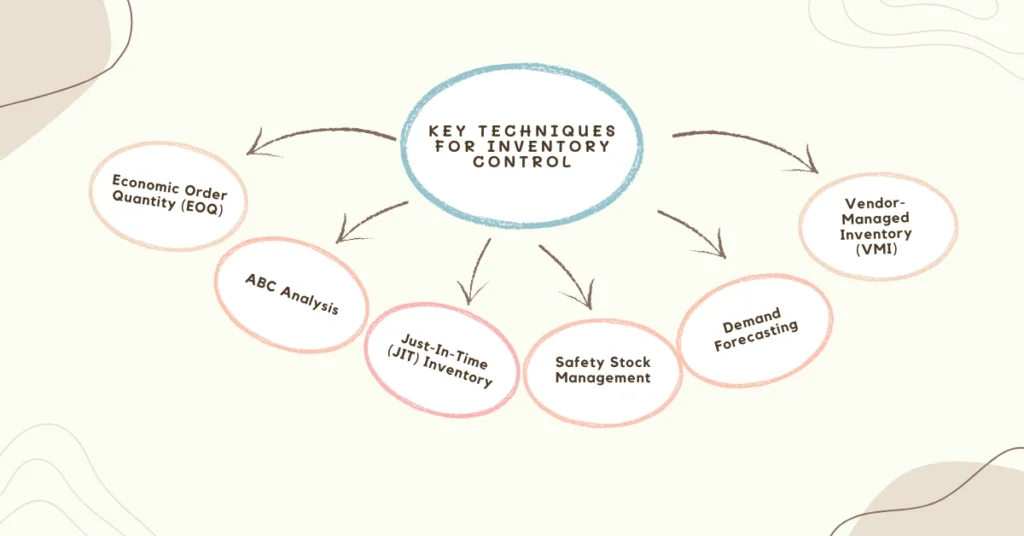

Key Techniques for Inventory Control

To help you choose the best inventory controlling techniques for your business, here are some of the most effective and widely adopted methods:

1. Economic Order Quantity (EOQ)

EOQ is one of the simplest purchasing inventory control techniques, which aims at finding the ideal quantity of order in order to reduce total inventory costs. This technique was employed to determine the level to which the total cost of acquiring and storing inventory is the lowest. EOQ helps organizations to keep inventory levels under check to avoid having too much stock or that physical stock is inadequate.

The EOQ formula takes into considerations demand, ordering and holding costs to give an accurate optimal order quantity. For this reason, it is widely used as one of the most applicable inventory control techniques as it assists inventory managers to determine the least price to pay for ordering frequency in order to achieve balanced physical inventory.

2. ABC Analysis

ABC Analysis is a powerful inventory control method that segments inventory into three categories based on their impact on overall revenue. The categories are:

- A: Expensive gadgets and other high-value goods with little sales volume.

- B: Moderate-value items with moderate sales volume (e.g., mid-range products).

- C: Low-value items with high sales volume (e.g., fast-moving, low-cost items).

This classification helps an inventory manager prioritize control over high-value items in Category A, while also applying appropriate types of control management to Category B and C items. For example, types of controlling for Category A might involve frequent reviews, while Category C could use automated reordering. ABC Analysis allows businesses to focus resources on the items that have the highest impact on revenue, making it an efficient techniques for inventory control.

3. Just-In-Time (JIT) Inventory

JIT Inventory is a technique of inventory control where products are ordered and received just before they are needed. This approach reduces storage costs and waste, as inventory is only held for short periods. JIT is particularly useful for businesses in industries with fast product cycles or high product turnover.

However, JIT requires a reliable supply chain, as there’s minimal buffer stock. When implemented correctly, JIT aligns inventory and control with real-time demand, making it one of the most responsive inventory control methods for minimizing holding costs and reducing overstock.

4. Safety Stock Management

In the inventory control method, safety stock is a particularly essential policy to avoid stock ingenue due to unpredictable demand. Thus by stocking up a little bit of additional stock, businesses are in a position to serve their customers as they do have a stock even if the sales increase unexpectedly. These following inventory control technique is particularly useful for the companies who have to face the seasonal demand or who have the longer lead time.

Managing safety stock involves setting a minimum threshold that triggers reordering. This buffer helps ensure that the company doesn’t lose sales due to stockouts, offering a practical solution for maintaining balance in inventory and control.

5. Demand Forecasting

Through demand forecasting, factors such as past sales data, current trends and customer consumption pattern are utilized in an endeavour to predict future consumption levels. Using this inventory control method, businesses can be assured of supporting the existing or new demand so as not to incur stock out or overstocking.

Demand forecasting is among the most data-driven techniques for inventory control. With accurate forecasting, businesses can optimize their inventory control techniques by purchasing the correct quantities at the right time. This not only enhances cash flow but also improves customer satisfaction by ensuring that products are always available.

6. Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory, abbreviated VMI is a type of inventory management in which the management of inventory levels in the retailer’s system is handled by the vendor. This makes it the supplier’s cycle to determine the when and frequency of inventory replenishments; the arrangement means that there are always new product supplies with the retailer having minimal work involving stock management.

VMI benefits inventory and control because it establishes a good relationship between the supplier and the retailer. It helps to allow the inventory manager to keep operations very smooth and carry out most of the work related to it and allow him to concentrate on providing service to the customers. This method is the most suitable for large production of standardized low margin products as handling time could translate to huge cost.

Also Read | How to identify your target audience

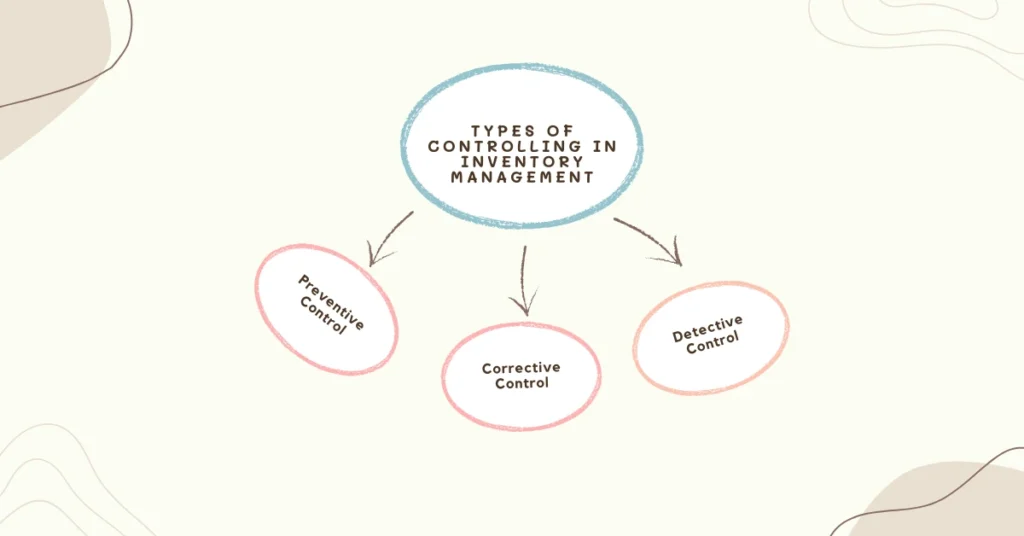

Types of Controlling in Inventory Management

Inventory management involves various types of controlling to ensure accuracy, cost efficiency, and high service levels. Understanding these types of control management can help businesses implement the right strategies:

Preventive Control: Preventive control targets to consider and control inventory problem before it actually happens. This inventory control technique has a reality of basing on the forecasts and the monitorings that are conducted. This is an important way through which business can avoid stock out and at the same time minimize the risk of getting stock in this was by predicting change in demand or supply chain interruptions.

Corrective Control: Corrective control addresses discrepancies after they have occurred. If actual inventory levels differ from projected levels, corrective actions are taken. This could involve adjusting reordering schedules or revising safety stock levels. Corrective control is crucial for realigning inventory and control when deviations occur.

Detective Control: Detective control strives to reveal weaknesses or mistake in implementing the inventory control methods. Periodic full stock taking, cycle counting, and performance appraisal assist organizations to detect areas where they lack effective inventory controlling tools and procedures.

Implementing a mix of preventive, corrective, and detective controls enables companies to tailor their types of control in management to meet their unique inventory needs, ensuring smooth and efficient operations.

Roles and Definition of an Inventory Manager

An inventory manager definition covers the professional that has responsibility for controlling and efficiently managing the inventory. Inventory managers are directly involved in the application of inventory control techniques and making modifications in accordance with the needs of the enterprise. Using inventory information, and forecasting demand, its agents guarantee that the inventory control techniques adopted are in harmony with the business aims.

An effective inventory manager also reviews also evaluates, other indicators like turnover rates, carrying costs, and occurrence of stockouts and make right adjustments to the inventory control techniques being applied. Due to their knowledge of inventory and control procedures the organizational efficiency and financial performance gain a positive impact.

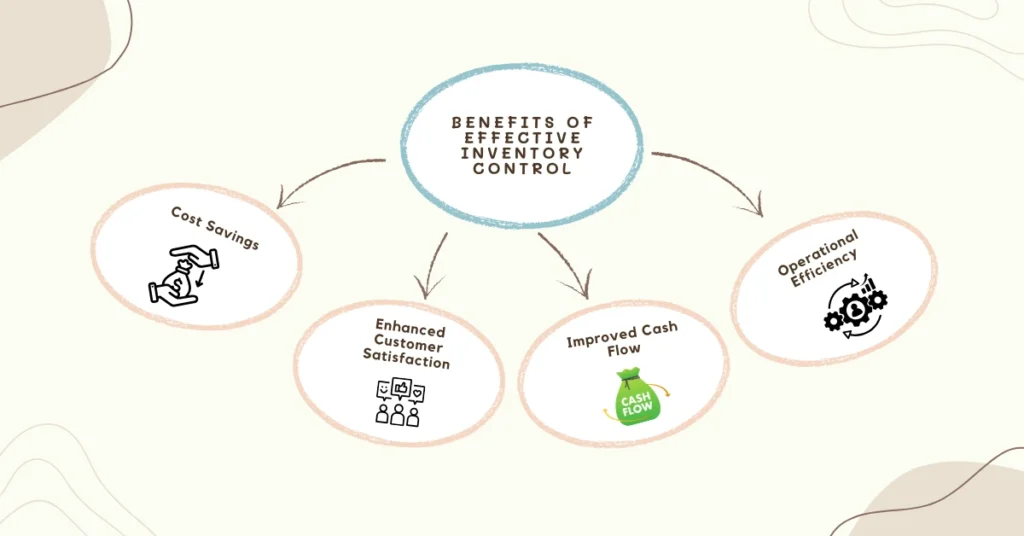

Benefits of Effective Inventory Control

The advantages of implementing effective techniques for inventory control are numerous. Here are some key benefits:

- Cost Savings: It was also seen that when organizations employ techniques such as EOQ or ABC Analysis along with JIT then they can cut down overall expenses on storage and control of inventory. Sustaining good stock control also helps avoid accumulation of too much stock thus enabling manager to free up capital so as to invest in other productive resources.

- Enhanced Customer Satisfaction: Thus, many businesses should ensure that they keep sufficient stocks of the products to enable them satisfy the customer needs. That is why if the right inventory control techniques are employed, then customer satisfaction and retention rates are bound to rise.

- Improved Cash Flow: Overstock has a limitation because it reduces the amount of money that is trapped in raw materials, work in progress, finished goods and services that are yet to be sold. In general, proper inventory controlling can enhance the cash flow thus enabling more reinvestment on some growth prospects.

- Operational Efficiency: Amidst the different types of control management such as the preventive and corrective control for instance, businesses can reduce or eliminate inefficiencies in its process hence enhancing productivity. This makes it easy to save on cost, avoid wastage and improve on the effective utilization of resources in the account.

How to Choose the Best Inventory Control Technique

The best methods of inventory control require a company’s business model, types of products and demand patterns for the products under consideration. Here’s a guide to help:

- Small Retailers: Derive advantages from using ABC Analysis and Safety Stock for the proper organization of various types of inventories.

- Manufacturers: Typically use EOQ and JIT Inventory when manufacturing many items and for very little storing.

- E-commerce Platforms: Where it is flexibility and responsiveness to changing market conditions, the effectiveness of Demand Forecasting, and Vendor-Managed Inventory cannot be ignored.

It helps one to appraise the different inventory control techniques in respect to the entrepreneur making sure that the required technique is selected used and optimized.

Common Challenges and Solutions in Inventory Control

While techniques of inventory control offer numerous benefits, they come with challenges:

- Inaccurate Demand Forecasting: Application of big data analytics and predictive software help in developing better forecast models for better inventory control and less incidence of stock out situation.

- Excessive Inventory Costs: Cycle counting, Break fixed inventory into small sub units for easy audits and inventory tracking can help in preventing excess stock and holding costs.

- Stockouts: The inventory control technology that can mitigate a risk of stockout include Safety Stock and Demand Forecasting. We find that acquiring software to support inventory control methods can also address most of the challenges since it is possible to automate and improve the accuracy of inventory and control methods.

Conclusion

There has however been a need to have proper stock control especially in respect to inventories hence of essence to have proper controls of stocks. About techniques for inventory control such as EOQ, ABC analysis, and JIT can improve business activities and cut expenses properly satisfying the customers. Selecting appropriate inventory control methods does not only increase the revenue but enhances the proper inventory control mechanism. In the implementing of these or some of these techniques, you should focus on those that will meet your business needs for the most.

People also ask

What are inventory control techniques?

Techniques of Inventory Control. Several methods are used in inventory control to keep an eye on the flow of goods in a warehouse. Batch tracking, safety stock, Last In, First Out (LIFO) and First In, First Out (FIFO), and ABC analysis are four common inventory control techniques.

What are the 4 types of inventory?

The four categories of inventory that are most frequently utilised are finished goods, work-in-progress (WIP), raw materials, and maintenance, repair, and overhaul (MRO).

What is basic inventory control?

The practice of controlling a company’s inventory levels, whether they are kept in-house or dispersed over multiple sites, is known as inventory control, or stock control. It includes handling products from the moment they are in stock until they are either disposed of (which is not ideal) or delivered to customers.